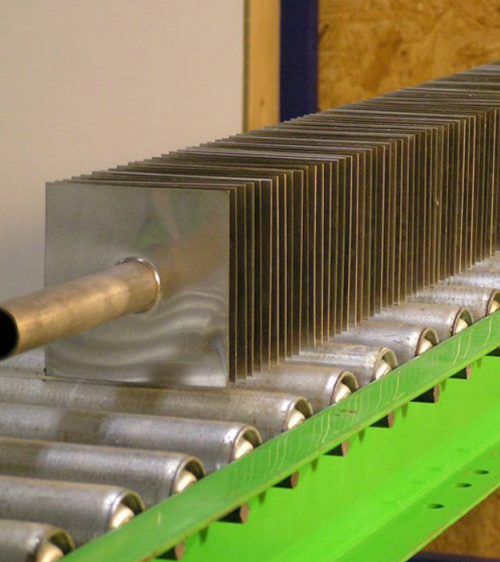

Stamped Fin Heat Exchangers for an Industrial Processing Application

Custom Stamped Fin Heat Exchangers

Fin Tube Products, Inc. was contracted to manufacture a large series of stainless steel stamped fin tube heat exchangers used to transfer heat in a large industrial processing application. Manufactured to meet precise customer specifications, each assembled heat exchanger unit consisted of a 12 foot long, 1 inch diameter individual tube, weighing 45 pounds, and various fins measuring 2, 4, and 4.5 square inches.

Using Fin Tube Products, Inc. Finbraze® process, individually stamped fins were brazed to the tube in our hydrogen atmospheric brazing furnace. Holding tolerances as low as ± .005 of an inch, we manufactured these finned tube heat exchangers from a combination of .030 inch thick materials, including stainless steel, carbon steel, and CuNi Alloy 715.

The heat exchangers were manufactured to withstand 1200°F temperatures and possessed a smooth, 45 RA finish. In order to ensure that these units met customer expectations, a series of in-process testing was performed in accordance with Fin Tube Products’ quality control system. In addition, the products’ quality was also verified by an onsite independent testing company.

Formed to our customer specifications, Fin Tube Products built more than 72,000 feet of these stainless steel stamped fin tube heat exchangers for our client, providing just-in-time delivery of all finished parts.

| Product Name |

Stamped Finned Tube Heat Exchanger |

| Product Description |

This Stamped Finned Tube Heat Exchanger is used for the transfer of heat in a large industrial processing application. |

| Capabilities Applied/Processes |

Manufactured to the customer specifications.

Packaging

|

| Equipment Used to Manufacture Part |

Hydrogen Atmospheric Brazing Furnace |

| Overall Part Dimensions |

Material Thickness: .030″ Tube Diameter: 1.00″ |

| Tightest Tolerances |

±.005″ |

| Material Used |

CuNi Alloy 715 Carbon Steel |

| Material Finish |

40 RA |

| Special Features |

Multiple Fin Dimensions |

| In Process Testing/Inspection Performed |

In process testing in accordance with Fin Tube Products, Inc.’s quality control system. |

| Estimated Part Weight |

45lbs Per Tube |

| Industry for Use |

Industrial Heat Exchanger |

| Production Volume |

Volume: 72,361 |

| Delivery Time |

Just In Time (J.I.T.) |

| Standards Met |

Formed to the Customer Specifications |