Finbraze® Finned Tubing for the Industrial Heat Exchanger Industry

Industrial FINBRAZE® Finned Tubing

Using our advanced Finbraze® brazing process, we manufacture a series of finned tubing that is used within various heat exchanger applications. The finned tubing is available in all current standard industrial sizes, and can be easily coiled or formed.

Meeting customer specifications, each finned tube can have similar or dissimilar metal combinations between the tube and fins. The product pictured, for example, possesses copper fins that were brazed onto a stainless steel tube. Our finned tubing is also manufactured to withstand tempe...

Miniature Finned Tubing for the Cryogenic, Aerospace & Biomedical Industries

Custom Miniature Finned Tubing

This miniature finned tubing, pictured, was manufactured by Fin Tube Products, Inc. to work within low-temperature cryogenic or biomedical applications. We developed the individual tubing components to meet various customer product requirements. We currently manufacture 2,000 to 3,000 feet per month of these miniature parts, which are formed using a combination of helical winding, soldering, or Finbraze® operations.

Meeting tolerances as low as ± .0003 of an inch, the tubes are constructed from a combination of industry certified 70/30...

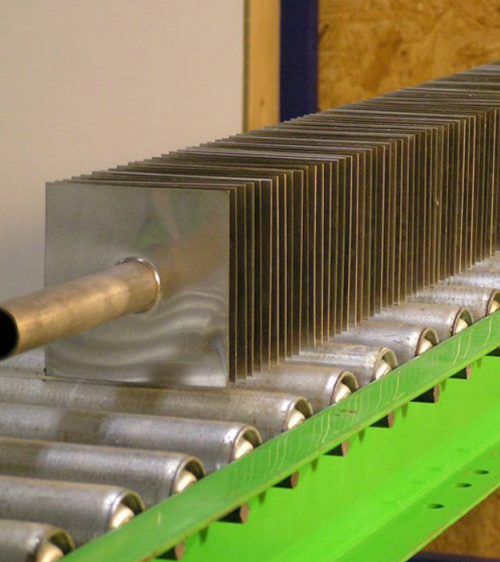

Stamped Fin Heat Exchangers for an Industrial Processing Application

Custom Stamped Fin Heat Exchangers

Fin Tube Products, Inc. was contracted to manufacture a large series of stainless steel stamped fin tube heat exchangers used to transfer heat in a large industrial processing application. Manufactured to meet precise customer specifications, each assembled heat exchanger unit consisted of a 12 foot long, 1 inch diameter individual tube, weighing 45 pounds, and various fins measuring 2, 4, and 4.5 square inches.

Using Fin Tube Products, Inc. Finbraze® process, individually stamped fins were brazed to the tube in our hydrogen atmospheric brazing fur...