Finbraze®

Finbraze® Finned Tubing

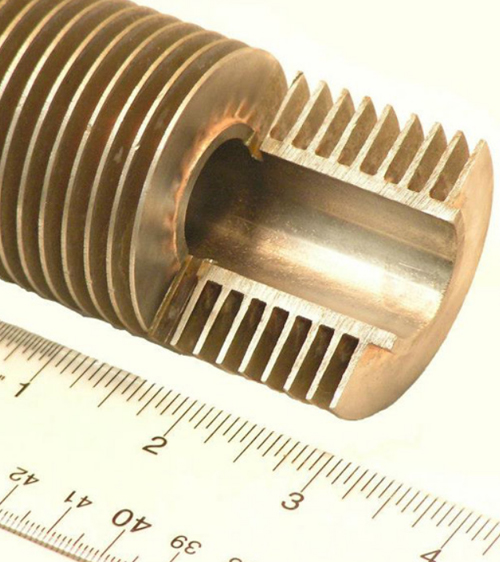

The brazed finned tubing from Fin Tube Products, Inc. is the most suitable for higher-temperature applications. The Finbraze® process creates a metallurgical bond between the tube and fin, which results in a stress-free, uniform, and non-porous contact, allowing for thinner tube walls compared to a welded fin-to-tube joint.

The Finbraze® process is done in-house with our Controlled Atmospheric Brazing Furnace. Advantages to the Finbraze® production of finned tubing include increased heat transfer, improved strength and durability, and a more cost-effective process. If you need finned tubing for a higher temperature application, look no further than the brazed finned tubing from Fin Tube Products, Inc.

What Are Finbraze® Finned Tubes?

Tube-Fin Heat Exchangers are another term used when referring to applied fin tubings. Simply put, it’s a tube, a different material that allows the fin to be placed or used. The fin can be of any size but is generally a thin metal. Furthermore, it will then make an annular fin in the form of a coil around the tube. In turn, it enhances the surface for more optimized cooling efficiency.

Through tension winding, soldering, brazing, or welding, a solid mechanical link is formed between the tubes. You can combine two contrasting materials to benefit from both. However, comparable metals are utilized in more prevalent applications. However, it is dependent on the application and uses.

Remember that each of the materials used has its own advantages and considerations. But it largely depends on end use and its overall effect on performance and efficiency. An aluminum fin and a stainless steel tube can help improve and maximize cooling efficiency in the cooling industry.

On the other hand, copper fins provide excellent heat transfer. However, it’s more susceptible to corrosion. Stainless steel offers much lower heat transfer. At the same time, it’s not vulnerable to corrosion, unlike copper. Overall, using applied fin tubing offers excellent advantages if used correctly.

Advantages of an applied fin tubing

- You may use different materials to improve its cooling efficiency.

- The fin material can be the same or different from the tube material.

- It provides a more balanced thermal conductance on the two sides of the heat exchanger, allowing for a heat exchanger of the smallest possible size.

- The finned tube provides high thermal efficiency in a small space.

- The finned-tube heat exchanger has a large surface area in a small volume, which results in quick heat transfer.

- You may use an applied fin tubing for various applications in different industries.

Finbraze®

The FINBRAZE® product line from Fin Tube Products, Inc. is a helically wound (Annular fin) finned tube, to which we apply a nickel alloy and braze the fin to the tube creating a metallurgical bond between the fin and tube, making it the most suitable bond for higher temperature applications. FINBRAZE® bonding between the tube and fin ensures a stress-free, uniform, and non-porous contact. This finned tube bonding allows for thinner tube walls compared to a welded fin-to-tube joint. The FINBRAZE® process is done in-house with our Controlled Atmospheric Brazing Furnace.

FINBRAZE® tubing is perfect for any application that exceeds 250 degrees Fahrenheit (121.11 degrees Celsius). If your application is 250 degrees to 950 degrees, FINBRAZE® is the product you are looking for. These finned tubes are designed to handle the harsh environment of cycling between environment temperatures and up to 1,150 degrees Fahrenheit (621.11 degrees Celsius). The Metallurgic bond created in our FINBRAZE® and CLADFIN® product lines prevents the fin from separating when the tube expands and contracts. The FINBRAZE® finned tubing keeps a reliable heat transfer rate between temperature cycling.

Finbraze product line offers several ways to increase the heat transfer rate. By Utilizing the increased surface area of an annular fin, you will get a higher heat transfer coefficient with this finned tubing. The result of this is a more efficient heat exchanger. Finbraze product line offers several ways to increase the heat transfer rate.

- Using dissimilar metals (copper, carbon steel, & Stainless Steel). Copper fins excel in heat transfer, though be wary of its susceptibility to corrosion. Meanwhile, stainless steel boasts a lower heat transfer rate, yet remains impervious to corrosion—a winner in durability. Remember, each material has its own unique strengths and considerations. With the unique chemical bond created by the Finbraze process, we can bond a copper fin to the same stainless-Steel tube. This will greatly increase the heat transfer efficiency. If the working environment is harsh on copper, see our Cladfin product line. However, it’s the final application and its impact on performance and efficiency that truly matters.

- Increase Fins Per Inch (fpi): Changing the fins per inch can either increase or decrease surface area.

- coiling

There are numerous advantages to the FINBRAZE® production of finned tubing.

- The use of dissimilar metals that cannot be welded such as copper fins on stainless steel tubes.

- The use of thinner (less expensive) tube walls that are not available when a resisted welded finned tube.

- The finned tubes can be formed over the fins after brazing. (Coils, U-bends…)

- Brazing is performed at a uniform temperature, eliminating stress at the joint areas.

- The use of our in-house Controlled Atmospheric Brazing Furnace allows for complete control over the production of your tubes.

- No Arcing. Eliminating the “Hot Spots” at the tube to fin joints as may occur in a welded finned tube.

Fin Tube Products offers several product lines (Finbraze, Cladfin, edge tension, and Miniature finned tubes) to significantly enhance the efficiency of your product, particularly the Finbraze finned tubes. Finbraze is available in a variety of materials and sizes to perfectly suit your specific needs. Our FINBRAZE® finned tubing can be seen in heat exchangers across many industries including Aerospace, Automotive, Medical, Petrochemical, Cryogenic, Electrical, and National Defense.

Get Your Finned Tubes From Fin Tube Products, Inc.

With the incredible features and benefits of finned tubings, especially the FINBRAZE® finned tubes, major industries can use them in different applications. These are components that enhance the efficiency of your equipment. Furthermore, these are available in various materials to suit your industry needs.

Don’t hesitate to contact us if you need help choosing the right finned tubes for your industry or request a quote today!

| Tubing Outside Diameter |

sizes

specific sizes.

|

| Tubing Length |

|

| Number of Fins per Inch |

|

| Fin Height |

|

| Temperature |

|

| Materials |

|

| Secondary Operations |

● “U” Bends, Coils Various Shapes. |

| Professional Associations |

● Cryogenic Society of America |

| Equipment List |

|