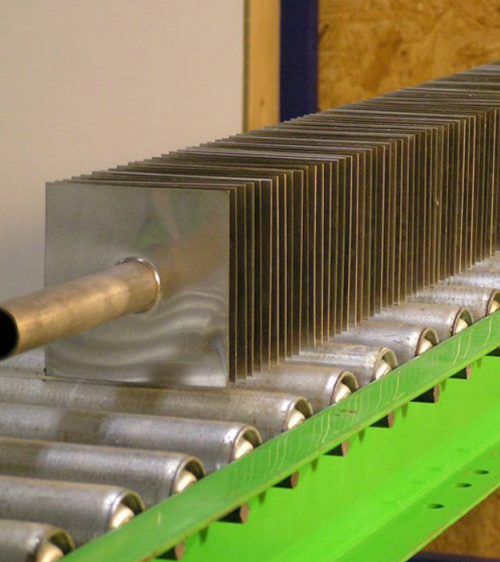

Stamped/Plate Fin

A stamped fin is a type of fin that can be manufactured in almost any shape or size. Despite the ability to create stamped fins in various shapes, square and round stamped fins are the most common.

Fin Tube Products, Inc. offers stamped/plate fins manufactured in almost any shape or size, but square and round are the most common. The fin is attached to the tube in our Controlled Atmospheric Brazing Furnace (CABF) with our FINBRAZE® process. This style of a fin is commonly referred to as a plate fin.

What is stamped or plate fin?

Stamped fin or plate fin heat exchanger is a heat sink that transfers heat away from sensitive components or devices by attaching thin metal plates to a conductor, such as a heatsink or metal block. The plate fins act as a thermal bridge between the component and the surrounding atmosphere, allowing heat to dissipate more quickly, and usually have 1 to 2 fins per inch.

Common Applications of Stamped/Plate Fins

Plate fins are used in a variety of heat transfer applications, including:

- air-cooled heat exchangers

- oil coolers

- radiators

In plate fin construction, the tubes are arranged parallel to each other and spaced evenly apart. The plate fin is then brazed to the tubes.

Plate fins are an efficient means of transferring heat because they have a large surface area that allows maximum heat transfer. They are often used in high-power applications, such as computer processors or power amplifiers, where space is limited.

They are also available in automotive and aerospace applications where weight and size are important considerations. Plate fins can effectively dissipate heat and protect sensitive components from damage when properly designed.

Advantages of Using Stamped/Plate Fin

Plate fin heat exchangers are known for their high performance and reliability.

- They provide efficient heat transfer without taking up much space, making them ideal for applications where size is a significant consideration.

- Plate fins also allow higher working pressures than other heat exchangers due to the increased surface area provided by the fins.

- Plate fins also tend to be much less expensive than other types of heat exchangers due to the simplicity of their manufacturing process.

- Stamped or plate fin exchanger is an excellent choice for heat transfer applications in sooting or fouling atmospheres. The plate fin design provides a large surface area for heat transfer, and the stamped fins offer high thermal efficiency. The plate fins also help to reduce the risk of fouling and provide superior resistance to shooting.

The plate fin design is easily cleaned and less likely to clog than other exchangers. As a result, stamped or plate fin exchanger is an ideal choice for heat transfer applications in sooting or fouling atmospheres.

The best solution for heat dissipation at Fintube Products, Inc

Fintube Products provides diversified finned tubing for your heat dissipation solutions. Plate fin heat exchanger solutions from Fin Tube Products, Inc. offer a reliable and cost-effective way to dissipate heat in high-power applications. Contact us today to discuss your plate fin needs!

| Tubing Outside Diameter |

|

| Tubing Length |

Stamped fins require a production run |

| Number of Fins per Inch |

Usually 1 to 4 |

| Fin Height |

4 1/2″ max |

| Temperature |

950° continuous 1150°F Intermittent |

| Materials |

|

| Professional Associations |

Cryogenic Society of America |

| Equipment List |

Atmospheric Brazing Furnace |